Review In procurement, total cost of Ownership includes all of the following except

Thủ Thuật về In procurement, total cost of Ownership includes all of the following except Chi Tiết

Hoàng Gia Trọng Phúc đang tìm kiếm từ khóa In procurement, total cost of Ownership includes all of the following except được Update vào lúc : 2022-12-24 22:26:03 . Với phương châm chia sẻ Kinh Nghiệm về trong nội dung bài viết một cách Chi Tiết 2022. Nếu sau khi Read tài liệu vẫn ko hiểu thì hoàn toàn có thể lại Comment ở cuối bài để Tác giả lý giải và hướng dẫn lại nha.For any organization, procurement is an essential business process. Organizations acquire goods and services from external suppliers the best price to expand, enhance operations, and optimize business performance. Being the indispensable business catalysts, procurement and procurement processes have evolved a rapid pace over the last few decades. The current procurement process is quite more complex and dynamic than the conventional one, wherein the buyers used to directly connect with the suppliers regarding competitive bids and attain short-term contracts that were fairly based on a pricing standpoint.

Nội dung chính Show- What is Procurement?Types of ProcurementTraditional Procurement vs. Strategic ProcurementProcurement ModelsThe Importance of Data in ProcurementProcurement Solutions - How they can Help Your BusinessHow to Choose the Right Procurement Solution for Your BusinessBest Procurement PracticesWhat Next? The Future of ProcurementWhich of the following cost elements is included in inventory carrying cost?Which of the following reflects or does not reflect a strategic focus on procurement?What is a characteristic of supply base reduction?Which of the following approaches offers the most flexibility quizlet?

Current cutting-edge procurement processes are no longer a luxury but a necessity for businesses across the globe. These aim achieving substantial cost reductions, exponential product development speed, and quality assurance. Today's organizations that aim to stay competitive all times must invest in ensuring due diligence of suppliers dispersed across a vast geographical domain before locking in on any long-term contract decisions. Striving to achieve demanding performance improvements across the entire supply chain process, especially in procurement, is unarguably the cornerstone for organizations.

We will explain procurement and how it is contextually beneficial for businesses in detail. You will also learn how to use this knowledge to achieve your business objectives.

What is Procurement?

Procurement can be referred to as the range of activities undertaken by businesses in obtaining goods and services. While procurement generally refers to the final stage of purchasing, it can also include the entire procurement process overall. Organizations can function as either the buyer or the seller though the focus is generally on the soliciting company. In a nutshell, procurement is referred to as performing "the five rights": getting the right quality, in the right quantity, the right time, for the right price, from the right source.

Today's business landscape is getting competitive with a plethora of world-class competitors, domestic and international. This has encouraged organizations to improve their internal processes to stay competitive. An abundance of competitors and choices has conditioned customers to settle for higher quality, faster delivery, and products and services customized to their individual needs a lower total cost.

Several factors drive an emphasis on optimal procurement strategy, processes, and execution. Some of the key ones include:

Cost efficiency and increased availability of information resources among entities in the entire supply chain, which eliminate potential time delays in the network.Domestic and international market-level competition. This requires organizations to be fast, agile, and flexible all times.Ever-evolving and demanding customer expectations and requirements.The ability of an organization's procurement and supply chain to identify and mitigate risk minimizes disruptions in both supply and downstream products or services to mitigate the impact on lost sales. With evolving customer needs, organizations and their suppliers must be responsive or face the prospect of lost opportunities, and revenue share.No business in the world is so self-sufficient that they have everything available internally. They tend to depend on other businesses when they need to buy goods and services that are essential to their business operations. In this context, it is essential to understand that the procurement process isn't just about purchasing goods or services to run day-to-day operations. It extends to ensuring that the company gets added value in the long run too.

Holistically speaking, purchase decisions depend on delivery time, product quality, intrinsic value, and competitive pricing. The impact of procurement on the rest of the business functions is undeniable. Any misstep can derail timelines across a plethora of business processes. This is why organizations need to establish a more robust procurement and supply chain management strategy for added business benefits, success, and continuity. Thus, procurement can again be considered a holistic strategic approach to identifying, planning, and acquiring the organization's current and future needs. Pursuing strategic responsibilities for the same can dictate the long-term success and growth of organizations.

Before we delve deeper into the procurement process, let's take a quick look the key objectives world-class organizations have pertaining to procurement.

Procurement Objectives

Objective #1 - Supply Assurance

procurement tends to support the needs of operations through the purchase of services, raw materials, and varied components. It can also support the requirements during the physical distribution endeavors, new-product/service development, and outsourcing of key processes. As a massive proportion of the responsibility for managing key business processes is reliant on suppliers, procurement must provide an uninterrupted flow of high-quality goods and services. Supply assurance is critical in this context here; in the lack of which, maverick buying may rise to the forefront.

Objective #2 - Effective Management of Procurement Process

Determining staffing levels, explicitly adhering to administrative budgets, and equipping the workforce for existing and potential procurement needs are some of the key ways organizations manage their procurement processes efficiently. Introducing improved buying channels within the procure-to-pay systems that aim achieving improved spending visibility, efficient invoicing and payment, and user satisfaction are also beneficial for organizations. Procurement teams must be focused on continuously improving transactional-level work through efficient purchasing systems that help manage multi-stakeholder relationships and performance. Talent management has emerged as an important task for procurement, as the need for qualified purchasing personnel is growing globally, with organizations expanding their production boundaries exponentially.

Objective #3 - Supplier Performance Management

For effective procurement in today's context, the selection, development, and maintenance of suppliers, otherwise referred to as supplier performance management (SPM), is pivotal. Robust supplier performance management requires procurement teams to manage relationships with external suppliers effectively and develop reliable, high-quality supply sources.

Objective #4 - Integrated Supply Strategy Development in Alignment With Business Goals

Supply management may fail to develop strategies and plans that align with or support organizational strategies due to a host of reasons such as:

Lack of historical participation of supply personnel in the C-suite level business planningFailure to realize the ultimate potential of the best-in-class procurementThe strategy development process takes place on four levels:

- Corporate Strategies: These strategies are concerned with the acquisition and allocation of resources to these business units.Business Unit Strategies: These strategies are concerned with the scope or boundaries of each business and the links with corporate strategy and (2) the basis on which the business unit will achieve and maintain a competitive advantage within an industry.

- Supply Management Strategies: These strategies, which are part of a level of strategy development called functional strategies, specify how supply management will (1) support the desired competitive business-level strategy and (2) complement other functional strategies (such as marketing and operations).

- Category/Sourcing Strategies: These strategies specify how a group tasked with developing the strategy for the specific category being purchased will achieve goals that, in turn, will support the supply management, business unit, and eventually corporate-level strategies.

The need of the hour for the businesses is to not regard their procurement personnel as the technical backbone but also as key catalysts in the decision-making processes. procurement personnel must be solicited for their opinions on supply market intelligence, budget forecasts, and other insights for driving highly strategic business planning.

Key Benefits of Having A Streamlined Procurement Process

Organizations increasingly realize the power and the role procurement plays in streamlining their operations with a high-growth and revenue intent. Effective procurement is essential when it comes to gaining a competitive advantage. Additional benefits that can accrue from streamlining the procurement process are:

The primary task of the procurement department is to get the right kind of suppliers the right price. The company can then vet the suppliers from multiple business standpoints and proceed with the supplier that offers the most lucrative business benefits. Tactically, companies can insist on discounts and warranties that are usually forgotten by non-specialists. Broadly speaking, this involves timely delivery of orders and fair pricing by the supplier.

Stakeholder management is a crucial aspect of procurement. Stakeholders can be classified as either internal or external. Internal stakeholders include budget owners, finance and legal departments, and senior management. External stakeholders include vendors, suppliers, and other parties that an organization depends on for procurement. Maintaining a positive relationship with these stakeholders is necessary for long-term success.

On the other hand, organizations are increasingly seeking to increase the proportion of parts, components, and services that are outsourced so that they can concentrate on their own core areas of specialization and competence. This further increases the importance of managing and nurturing the relationships amongst stakeholders.

An enterprise's procurement department has the potential to drive organization-wide innovation. Selecting suppliers that facilitate innovation, seeking new ways to create value for the business, and coordinating between internal and external stakeholders are all key to gearing business processes towards innovation.

Ensuring customer satisfaction has always been a key objective for organizations, which evidently rely on the quality of products and services extended to the end customers. Procuring the right raw materials and requisite services from reliable suppliers can assist organizations in ensuring that their customers get the best value for their money.

- Enhancing the Speed to Market

The time to market is an indispensable KPI for organizations in today's context to acquire the much-competed mindshare among the target audiences. Products and services that are queued up next in the line might often fail to garner the desired impression, which might have tangible and intangible repercussions for the organization. Procurement, acting as the liaison between suppliers and organizations, can play a pivotal role in expediting product development endeavors. Studies cite that companies that involve suppliers early, compared to companies that do not involve suppliers, achieve an average 20 percent improvement in materials costs, material quality, and product development times. Bringing in the suppliers' POV can also help organizations solicit improvement suggestions. The right procurement strategy and supplier collaboration can help organizations add new value and contribute to increasing competitiveness.

While a certain degree of risk is associated with any business process, the risk rises up by several notches when a business has to depend on suppliers dispersed across geographies. The risks can be major and minor in nature, and the extent of severity. These risks are magnified by sourcing strategies that emphasize global sourcing, single sourcing, and JIT inventory. Having a robust procurement process and strategy in place can mitigate and manage these additional risks. Organizations can entrust their procurement teams to consistently monitor their supply base for risk and develop business continuity plans to mitigate these risks.

Procurement Enablers

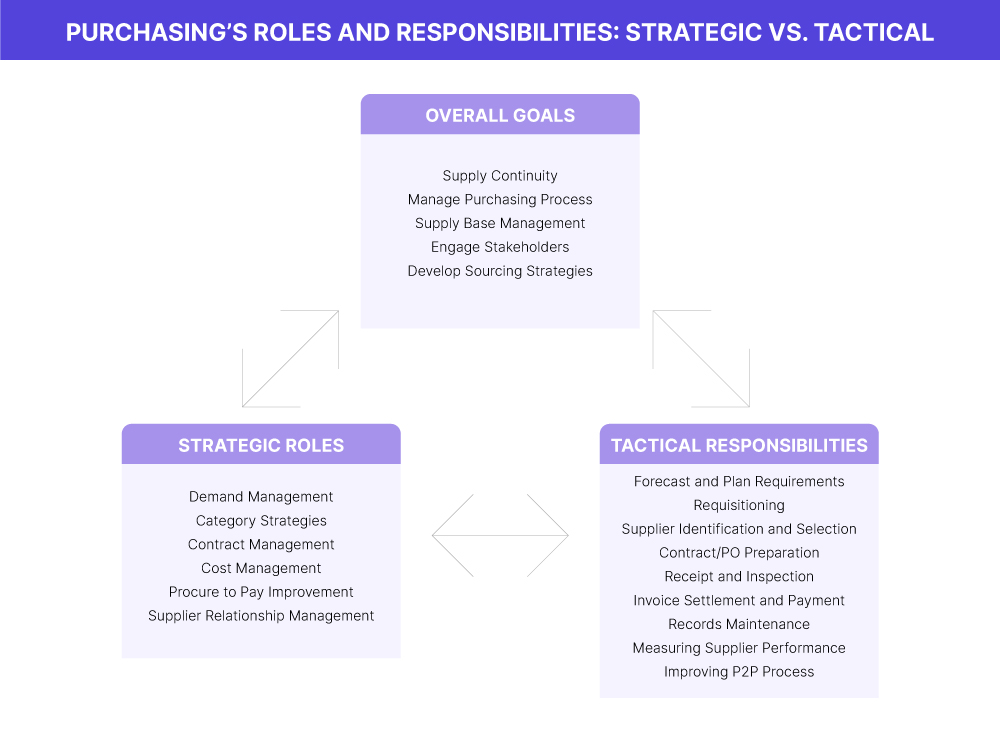

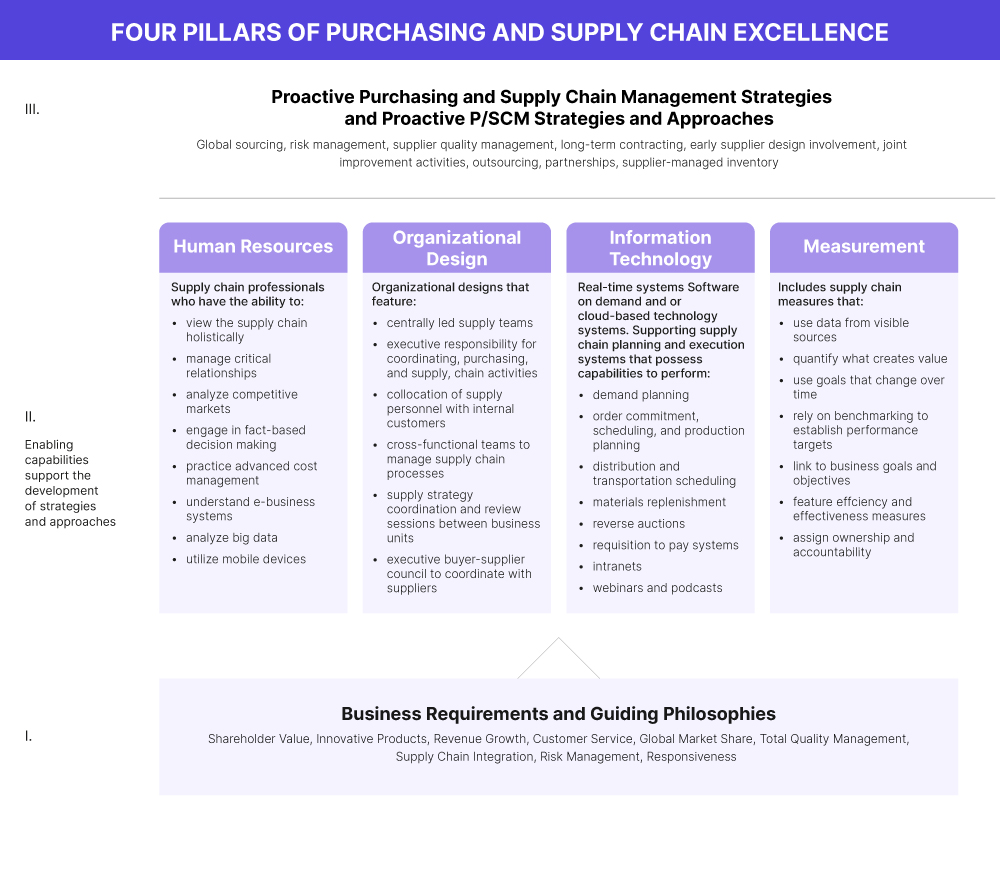

Procurement enablers provide the support to organizations that makes the development of progressive strategies and approaches possible. The four enablers model establishes that organizations have certain guiding philosophies and requirements that form the foundation of all supply chain activities. These guiding philosophies and requirements are mostly concerned with aspects such as globalization, customer responsiveness, or supply chain integration. These procurement enablers, in turn, support the development of strategies and approaches that are not only in alignment with an organization's philosophies and requirements but also support the attainment of purchasing, supply chain, and organizational objectives and strategies.

Capable Human Resources

The key to the success of any company is the quality of its employees. This is certainly true for purchasing. Exhibit 1.6 identifies, from previous research, the various kinds of knowledge and skills demanded of today's supply chain professional. Previous research indicated that the top five knowledge areas for purchasers should include: (1) supplier relationship management, (2) total cost analysis, (3) purchasing strategies, (4) supplier analysis, and (5) competitive market analysis.12 Effective supply chain management requires close collaboration with suppliers as well as internal coordination with engineering, procurement, logistics, customers, and marketing to coordinate activities and material flows across the supply chain. These relationships with key suppliers become the basis for purchasing strategies.

Cost management has become an integral part of purchasing and supply chain management. With an inability to raise prices to customers, cost management becomes essential to long-term success. Purchasing specialists a major U.S. chemical company, for example, evaluate major supply decisions using total cost models with data provided by suppliers and other sources. Another company requires its teams to identify upstream cost drivers past immediate suppliers, which the teams then target for improvement. These analyses of the total cost are then imposed upon the market situation and analysis of supplier capabilities to arrive an overall purchasing strategy.

Gaining access to the right skills will require a sound human resources strategy that includes the internal development of high-potential individuals, recruiting talent from other functional groups or companies, and hiring promising college graduates.

Proper Organizational Design

Organizational design refers to the process of assessing and selecting the structure and formal system of communication, division of labor, coordination, control, authority, and responsibility required to achieve organizational goals and objectives, including supply chain objectives.13 Formal charts portray only a portion of the workings of an organization. For example, many organizations are now utilizing center-led supply management structures.

These hybrid forms of organization utilize various coordinating mechanisms that are not part of a formal organizational chart. The use of teams as part of supply chain design will continue to be important. However, managers should use teams selectively. Few studies have established a clear connection between teaming and higher performance, and even fewer have quantitatively assessed the impact of teaming on corporate performance. The use of organizational work teams to support purchasing and supply chain objectives does not guarantee greater effectiveness.

Real-Time Collaborative Technology Capabilities

The development of information technology (IT) software and platforms that support an end-to-end supply chain have grown rapidly in the twenty-first century. There are cloud-based storage systems, a new wave of mobile devices that permit skyping for visual meetings, and shared software platforms that permit visibility between all-size supply chain partners. Further identification technologies such as radio frequency identification (RFID) and voice recognition systems are getting better and better.

Regardless of the type of information technology platform or software used, supply chain systems should capture and share information across functional groups and organizational boundaries on a real-time or near-real-time basis. This may involve transmitting the location of transportation vehicles using global positioning systems (GPSs), using Internet-based systems to transmit material requirements to suppliers, or using barcode technology to monitor the timeliness of receipts from suppliers. RFID tags are being used in more applications to capture real-time data about material and product movement across the supply chain.

Right Measures and Measurement Systems

The right measures and measurement systems represent the fourth pillar supporting purchasing and supply chain excellence. Unfortunately, there are many roadblocks between measurement and improved performance. Some of these include (1) too many metrics, (2) debate over the correct metrics, (3) constantly changing metrics, and (4) old data. Overcoming these roadblocks requires that the organization knows what it wants to measure, has a process in place to measure it, and has accessibility to the right data. The next step involves taking action on the measurement data.18 Finally, as with any planning system, the targets are revised to reflect the realities of the marketplace, competition, and changing goals of the organization.

Why is measurement so important? First, objective measurement supports fact-based rather than subjective decision-making. Second, measurement is also an ideal way to communicate requirements to other supply chain members and to promote continuous improvement and change. When suppliers know their performance is being monitored, they are likely to perform better. Many firms use the measurement system not only to improve future supplier performance but also to recognize outstanding performance. The measurement process also helps determine if new initiatives are producing the desired results. Finally, measurement may be the single best tool to control purchasing and supply chain activities and processes.

Although there is no definitive or prescriptive set of supply chain measures, and there certainly is no one best way to measure supply chain performance, we do know that effective measures and measurement systems satisfy certain criteria. These criteria, which Exhibit 1.6 summarizes, provide a set of principles with which to assess supply chain measures and measurement systems.

These four enablers support the pursuit of progressive approaches and strategies that begin to define purchasing and supply chain excellence. If organizations ignore these areas, they will see their ability to develop progressive practices and approaches fall short of competitors that have stressed these enabling areas.

Procurement Life Cycle

The procurement lifecycle evolves according to the business needs. It can be understood as the steps that make up the process of buying goods. Effective procurement processes are critical for financial efficiency. It helps pay the right price and ensures timely delivery while ensuring you choose the best partners to work with. An optimized procurement lifecycle integrates strategy and management with the company's regulations. Procurement and automating this process in its entirety can create new market models for organizations in the ever-evolving and competitive global economy.

A Successful Procurement Process - The 7 Essential Steps You Should be Aware of

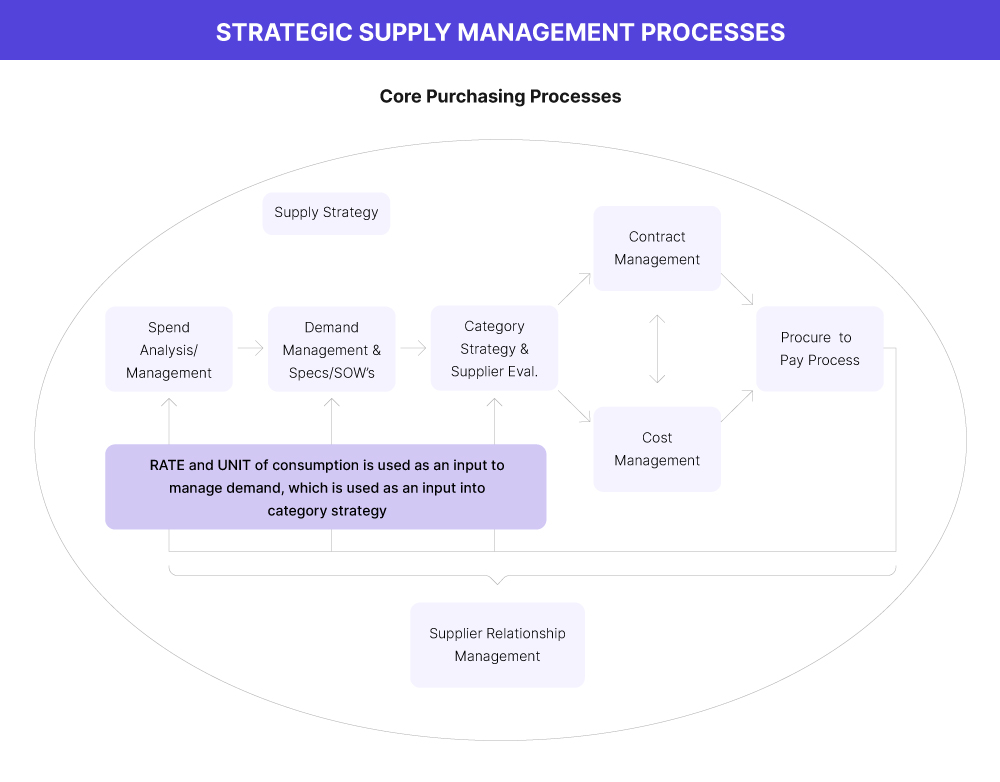

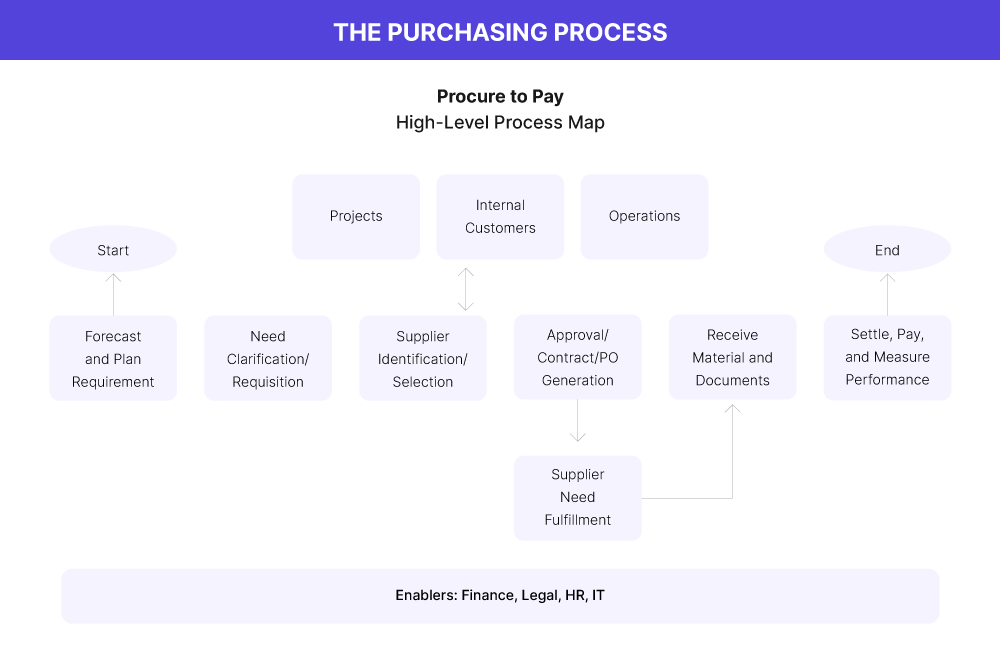

An essential aspect of building a robust procurement lifecycle in an organization is setting up a well-defined procurement process flow. Procure to pay process essentially involves the initial identification of requirements, procurement/purchasing of the item, receipt of the goods, and making the payments to the suppliers. There are two things to keep in mind while understanding the P2P process. First, the relative effort a company spends on P2P activities will differ greatly from one situation to another. Secondly, organizations can choose to gain a competitive advantage by performing these procurement steps in an automated manner. e-Procurement solutions automate routine purchase order preparation, whereas others use sourcing management teams to improve the outcome of supplier evaluation and selection efforts. An efficient P2P process therefore plays a pivotal role in ensuring the best utilization of people for the right set of activities and to perform a good spend analysis, which in turn will make the strategic procurement activities more effective.

Successful procurement processes follow best practices in the form of sub-processes:

Requirements Analysis Company-Wide NeedsIdentifying the requirements for each business unit within the organization is crucial. This step helps consolidate all the needs, so the procurement department gets company-wide visibility into who needs what and how much money is being spent.

In most cases, procurement departments have an annual or biannual planning process, whereby the spending pattern for the organization through a spend analysis is reviewed. Based on this, a forecast of what should be procured is chalked out. In certain cases, there may be a whole set of new requirements that have not been planned for, wherein purchasing personnel meet with internal customers to discuss their needs for the coming year.

To accomplish this objective of managing all third-party spending, supply management will need to work with a large number of stakeholders, including marketing, operations, engineering, R&D, finance, information technology, human resources, and other internal customers. Through structured dialogue, the procurement team will identify and plan for what these customers will be buying. These insights can then be translated into a forecast that is shared with the select suppliers. Of course, not all needs can be forecasted ahead of time. Situations arise when needs come up suddenly, which is not planned for, and for which there is no pre-existing supplier identified to provide the product or service required. Such needs are often managed through a spot buy approach, which is also discussed within the context of the P2P process. Besides, when creating a forecast for a needed product or service, internal customers may not always be able to express exactly what it is they will need a future point in time.

In such cases, purchasing may negotiate agreements with distributors for parts supply agreements. In other cases, a stakeholder may request to work with a specific service provider for temporary services,

consulting services, or software programming, but they cannot express exactly the type of labor requirement needed. Purchasing will then seek to create a contract with predefined costs for different classes of workers who can provide these services on short notice.

After requirements gathering, the next step is to search for the best suppliers. The step entails an evaluation process that scrutinizes quality, price, warranties, vendor reputation, and customer service. The suppliers who satisfy all these criteria get the giảm giá.

Once the need and its description are identified, one of two things can happen:

(1) The need is fulfilled by a supplier that has an existing contractual relationship with the buying company.

(2) The need is fulfilled by a new supplier that is not currently qualified to provide products and services to the firm.

In the first case, the P2P process moves quite smoothly. Through the need forecasting process, purchasing personnel has already identified which suppliers will be used to source the need, and they have already taken steps to evaluate and prequalify the supplier. Qualification is important, as the purchasing firm must ascertain that the supplier meets several criteria and evaluate whether it is qualified to do business and meet the needs of its internal customers in a satisfactory manner.

In the second case, where a supplier is not identified or when the internal customer requests that the need be fulfilled by a specific supplier of their choosing, purchasing faces a more difficult challenge. When internal customers purchase directly from nonqualified suppliers and try to bypass purchasing in the process, this is known as maverick spending. That is, customers are acting as a maverick; that is, they do not wish to use suppliers already deemed by purchasing as qualified to fulfill the need. Although some level of maverick spending is always going to occur in an organization, there are significant risks that can occur when it reaches high proportions.

Supplier Selection and NegotiationNegotiation is the most significant step before signing a contract with suppliers. This vital step may include discussions on price, delivery timelines, and terms and conditions. Supplier selection is a process that requires a huge amount of a firm's financial resources and is critical for the success of any organization. The primary objective during this stage is to reduce purchase risk, maximize overall value for the business, and develop long-term relationships between buyers and suppliers.

Competitive bidding and negotiation are two methods commonly used when selecting a supplier. Competitive bidding in the private industry involves a request for bids from suppliers with whom the buyer is willing to do business. This process is typically initiated when the purchasing manager sends a request for quotation (RFQ) form to the supplier. The objective is to award business to the most qualified bidder. Purchasers often evaluate the bids based on price. If the lowest bidder does not receive the purchase contract, the buyer has an obligation to inform that supplier of the reason it was not chosen for the contract.

Competitive bidding is effective under certain conditions:

- Volume is highThe specifications or requirements are clear to the sellerThe marketplace is competitive, which means it has an adequate number ofqualified sellers that want the businessBuyers ask for bids only from technically qualified suppliers who want thecontract, which in turn means they will price competitivelyAdequate time is available for suppliers to evaluate the requests for quotationThe buyer does not have a preferred supplier for that item

Buyers use competitive bidding when the price is a dominant criterion and the required item (or service) has straightforward material specifications. In addition, competitive bidding is often used in the defense industry and for large projects. If major non-price variables exist, then the buyer and seller usually enter into direct negotiation. Competitive bidding can also be used to narrow the list of suppliers before entering contract negotiation.

Negotiation is logical when competitive bidding is not an appropriate method for supplier selection. Face-to-face negotiation is the best approach in the following cases:

- When any of the previously mentioned criteria for competitive bidding aremissing.When the purchase requires agreement about a wide range of performancefactors, such as price, quality, delivery, risk-sharing, and product supportWhen the buyer requires early supplier involvementWhen the supplier cannot determine risks and costsWhen the supplier requires a long period of time to develop and produce the items purchased. This often makes estimating purchase costs on the part of the supplier difficult

After finalizing the supplier, a procurement manager needs to raise a Purchase Requisition (PR) order. The PR needs to include a description of the goods, the expected quantity, detailed supplier information, along with prices and the requisite approvals. Once the PR is released, the accounting department can issue a Purchase Order (PO) to the supplier. A purchase order is a document of an official offer issued by a buyer to the seller for the purchase of goods and services. Most purchase orders include details on standard legal conditions that the order (i.e., the contract) is subject to. Information may include details on the quantity of material (or service quantity), material specification, quality requirements, price, delivery date, method of delivery, ship-to address, purchase order number, and order due date. Having this documentation is an essential part of procurement as it makes the entire process manageable, correctable, transparent, and auditable.

For an item or group of items ordered repetitively from a supplier, procurement teams may issue a blanket purchase order—an open order, usually effective for one year, covering repeated purchases of an item or family of items. The major difference between a purchase order and a blanket purchase order is the delivery date and the receiving department. This information on the blanket order remains open because it often differs from order to order. Blanket orders eliminate the need to issue a purchase order whenever there is a need for material. After a buyer establishes a blanket order with a supplier, the ordering of an item simply requires a routine order release. The buyer and seller have already negotiated or agreed upon the terms of the purchase contract. With a blanket purchase order, the release of material becomes a routine matter between the buyer and seller and the procurement process is ultimately more streamlined.

Buyers usually tend to prefer a purchase order for initial purchases or a one-time purchase, which procurement professionals may also refer to as a "spot buy." Blanket purchase orders are most commonly laid out for production items that are ordered on a regular basis or for routine supplies.

Complete the Payment ProcessWhen a supplier receives a Purchase Order, a price invoice for the goods is sent. Payment is executed, and the goods are received; the procurement department then matches it to ensure quality and quantity. At this stage, it's important to note that the payment process depends on mutual understanding; it can be pre or post-delivery. Some companies have a cool-off period, so vendors have a strong incentive to deliver the right quantity and quality.

Audit Delivery of Goods/ServicesOnce the supplier delivers the goods based on the contractual terms, the procurement department can check to ensure quality expectations and quantity.

As with any multistage process, every Purchase Requisition, Purchase Order, and invoice needs to be tracked and the records saved.

Rehashing Procurement Process

No matter how effective an organization thinks its P2P process, there is always scope for improvements. In reengineering the procure-to-pay process, these following approaches are recommended by experts.

Securing top management support for the initiative and budgeting for the project is the stepping stone. Organizations can develop a list of key benefits and deliverables that will occur as well as document the cost of leaving the system in its current state rather than opting for improvements.Organizations must map existing processes and problems with the P2P cycle, identify the points of breakdowns and their key reasons.Organizations must understand the needs and requirements of the user groups. Several stakeholders such as maintenance, planning, project management, suppliers' accounts payable, and buyers, etc. might have certain issues that prevent them from using the existing procurement and supply chain system.Team redesign workshops should be leveraged by organizations to bring together key subject matter experts (SMEs) from each of the business units. Suppliers' opinions and active participation must be sought after to garner ideas and solutions for further improvements.Organizations can explore the existing technology solutions and then map out the business requirements that are aligned with the technology solutions available. Begin to estimate the cost of deployment and ensure that adequate planning and due diligence are taken this step.Following the workshops, organizations can define the new process and begin to pilot using the planned technology, which should take place in a real environment.Train and deploy other users based on the new processes and systems. Be sure to make the training appropriate to the specific functional unit and user groups.Monitor, update and improve the system, ensuring that catalogs are kept up to date. Hold periodic meetings with suppliers and user groups to solicit input and identify problems with the systems.Types of Procurement

We can split procurement into three types to understand it better.

Direct Procurement

This method includes purchasing raw materials, equipment, and wholesale goods, which directly contribute to the company's production processes. Direct procurement has a significant impact on the company's profit, performance, and efficiency.

Indirect Procurement

This method is commonly used in acquiring supplies or inputs that are not used in the manufacturing process but are necessary for daily operations, such as office supplies.

Service Procurement

Service procurement is the process of procuring people-based services for enterprise purposes. This could be in the form of hiring external consultants, specialty service agencies, or maintenance service providers.

Traditional Procurement vs. Strategic Procurement

Regardless of the size of the company, procurement has become essential. What differentiates small corner stores from large organizations is their purchasing processes. Traditional procurement processes have evolved beyond mere purchasing to strategic sourcing with extensive supply chain management.

The biggest difference between strategic and traditional procurement is that strategic sourcing is a dynamic process. In contrast, traditional procurement emphasizes the need to find a supplier based on prices.

Modern organizations are moving towards intelligent sourcing, which uses advanced technology to make the production process better and more efficient. It allows organizations to make accurate adjustments while saving costs and time.

Procurement Models

The procurement strategies can have a tremendous effect on the bottom line of the businesses. Those willing to evolve and improve their buying and purchasing methodologies have several procurement models their disposal. The 5 Models are:

All the tasks, decision-making, and control are performed autonomously.

With the network procurement models, the activity is connected across local units. The decision-making process is not independent but remains managed in some shape by various nodes on the network.

Decision-making and procurement processes are centralized. Some activity is beyond the scope of procurement, like calling off supply under a centrally negotiated contract.

This model is a combination of central and local. Some are managed the local level, and some are managed centrally.

The whole activity is managed across all local units while nodes exercise control of the network.

The Importance of Data in Procurement

procurement intelligence sustains cost optimization opportunities and also enables procurement organizations and departments to play a decisive role. Data is constantly referenced for predictive analysis. Procurement teams use this information to mold the entire decision-making process. They are able to predict and play along with global trends that shape market conditions. Developing an in-house database of procurement information can aid teams in functioning more effectively in their organizations.

Procurement Solutions - How they can Help Your Business

A business cannot work effectively without efficient and the best procurement solutions. These ensure that the products and services are acquired on time every time. Essential to manufacturing and business operations, procurement management can speed up production and reduce costs.

As procurement is a compliance-driven process, it can be cumbersome, time-consuming, and inefficient when performed manually. Modern procurement solutions are technological. They help a business manage the procure-to-pay process efficiently.

How to Choose the Right Procurement Solution for Your Business

Selecting the best procurement solution is complex, but there are criteria that can help make an informed decision based on features:

Implementing a procurement solution isn't as easy as it seems. Technical challenges aside, no one will initially accept the change, especially when it is challenging to learn. The right and ultimately the best procurement solution can help shorten the implementation phase to go live within days while saving time and costs substantially.

Technical glitches are all too common in any software. Ensure that the vendor gives you excellent customer support promptly. Evaluate different vendors on the basis of Mean Time Resolution of support tickets, responsiveness, and self-service capabilities such as an up-to-date knowledge base.

Evaluate Features and Plan CustomizationsAfter taking a demo, begin with an inventory of all the functionality in your present procurement system. Segregate between must-have and good-to-have features. Once this is done, discuss functionality that needs to be added. If the post-customization price is right, you can proceed with a purchase.

Best Procurement Practices

Procurement processes are evolving breakneck speed. The impacts of such accelerated technological and process changes can have far-reaching consequences for the business. Staying up to date with the latest trends isn't a choice anymore. It is crucial to follow the best practices in procurement that are current, tested, and practical. Here are some things every business should consider:

Transparency needs to become an integral aspect of procurement as a lack of it can result in reduced due diligence, hasty solutions, and improper contracts, and can create several implementation problems later on. Auditable procurement is a fast-evolving idea that has taken root in many organizations. Transparency helps businesses outperform competitors by prioritizing trust and accountability.

Procurement DigitalizationAutomation and digitization are always essential if a business wants to stay competitive. Technology, automation, and the cloud can help reduce manual processes, ultimately helping digitize procurement.

Improve supply chain communicationLack of communication in the procurement process can lead to supply chain disasters. Responsibility and roles need to be communicated well. With the advent of communication channels, it is much easier. However, companies need to create standardized communications for each stage so there is no confusion.

Decision-making is a complex process that involves numerous people across multiple departments and teams when it comes to supply chain management. Effective decision-making is the strongest defense against the unknown for any business. Supply chain management professionals design and implement decision-making processes that can potentially keep businesses one step ahead of the rest in a dynamic business environment.

The procurement decision-making process is complex and involves several stakeholders. Effective decision-making takes the centrestage here.

An effective decision-making process can be deemed as the best defense against the unknown for any organization when it comes to procurement. Many organizations efficiently involve their supply chain management professionals to design and implement decision-making processes that will keep the organization one step ahead in an ever-changing world.

What Next? The Future of Procurement

Purchasing and supply chain management today reflect a growing emphasis on the importance of suppliers. From a reactive approach to a more cooperative approach with selected suppliers, the supplier relationship management paradigm has been witnessing a substantial shift. The activities that the twenty-first-century purchasing organization must put in place are quite different from those of the recent past. Supplier design involvement, and development, the use of full-service suppliers, total cost supplier selection, supplier relationship management, strategic cost management, enterprise-wide systems (enterprise resource planning, or ERP) hosted on the "cloud" and integrated Internet linkages and shared databases available 24/7 are now deemed as ways to deliver value addition within the supply chain. At the same time, newer concepts continue to emerge, including enabling innovation in the supply base, contributing to top-line revenue growth, using mobile devices to monitor supply, and managing risks of a global-scale supply chain. Purchasing and more specifically procurement behavior is shifting dramatically to support the performance requirements of the new era.

To summarize, the reshaping of purchasing's role in the emerging global economy is underway in response to the challenges presented by worldwide competition and rapidly changing technology and customer expectations. The overall importance of the purchasing function is increasing, particularly for firms that compete in industries characterized by worldwide competition and rapid change. And, purchasing must continue to become more integrated with customer requirements, as well as with operations, logistics, human resources, finance, accounting, marketing, and information systems. This evolution will take time to occur fully, but integration is inevitable.

As new operating models in procurement proliferate, businesses need to digitize. IoT and related technologies, intelligent sourcing along with the cloud are revolutionizing this space. Procurement teams will continue to get more agile and lean in the future. The primary focus will be on activities with a high ROI. Embracing strategic re-evaluations and new technologies is the path forward in procurement. Automation will không lấy phí up highly-skilled resources and enable them to manage more categories. procurement will be expected to impact and control costs, which will require resources to upskill while eliminating those that cannot make the cut. A digitally native, robust, AI-powered procurement solution will unarguably be the future of procurement, and continue to disrupt the entire procurement ecosystem, holistically.

We Beroe understand how manual processes are the bane of procurement. This is why we think the way forward for enterprises is holistic software that is end-to-end automated. The right and the best procurement solution can help accelerate your day-to-day operations while becoming a competitive advantage.

Being the world's leading provider of procurement intelligence and supplier compliance solutions, we offer critical market information, analysis, and actionable insights that enable businesses across the world to make smart sourcing decisions.

Our AI-powered Procurement Productivity Suite can assist you in discovering global market information in real-time scale across 400 versatile categories, sourcing global data, and identifying reliable suppliers from a community of 4.2 million suppliers. We help you attain 360-degree visibility into your suppliers' compliance credentials and gauge the potential for impact-led disruptions in your supply chain. Manage procurement and supply chain risks like a pro with Beroe.

To learn how you can evolve with our robust, resilient, AI-powered digital procurement assistant Abi and us, get in touch.

Which of the following cost elements is included in inventory carrying cost?

Inventory carrying costs can be sorted into four categories: capital costs, storage costs, service costs and inventory risk costs.Which of the following reflects or does not reflect a strategic focus on procurement?

Supply Chain Test 1.What is a characteristic of supply base reduction?

Supply base reduction [SBR] is the process of deliberately reducing the number of active suppliers in the supply base. The motivation is to consolidate the organisation's spend to fewer suppliers and to leverage better value from those relationships.Which of the following approaches offers the most flexibility quizlet?

Which of the following approaches offers the most flexibility? ATO (Assemble to Order). Tải thêm tài liệu liên quan đến nội dung bài viết In procurement, total cost of Ownership includes all of the following except

Post a Comment